Sustainable Supply Chain

Definition and Scope “Conflict minerals” refer to metal minerals sourced from regions with armed conflict and human rights violations, primarily including gold (Au), tin (Sn), tantalum (Ta), and tungsten (W) from the Democratic Republic of the Congo and surrounding countries. These are commonly used in electronics manufacturing. Commitment and Policy As a responsible global enterprise, OSE commits to not using substandard metals from conflict-affected smelters and integrates this into supplier management.

Conflict Minerals Management

- Compliance with international and regional regulations prohibiting conflict minerals.

- Conducting due diligence on supply chains for metals including Au, Ta, Sn, W, cobalt (Co), and mica, following the OECD Due Diligence Guidance or equivalent frameworks.

- Requiring suppliers to sign declarations confirming no use of hazardous substances and sourcing only from Responsible Minerals Initiative (RMI)-certified smelters/refiners.

- Encouraging suppliers to ensure their upstream partners adhere to the same standards, avoiding any support—direct or indirect—of armed conflict or human rights abuses.

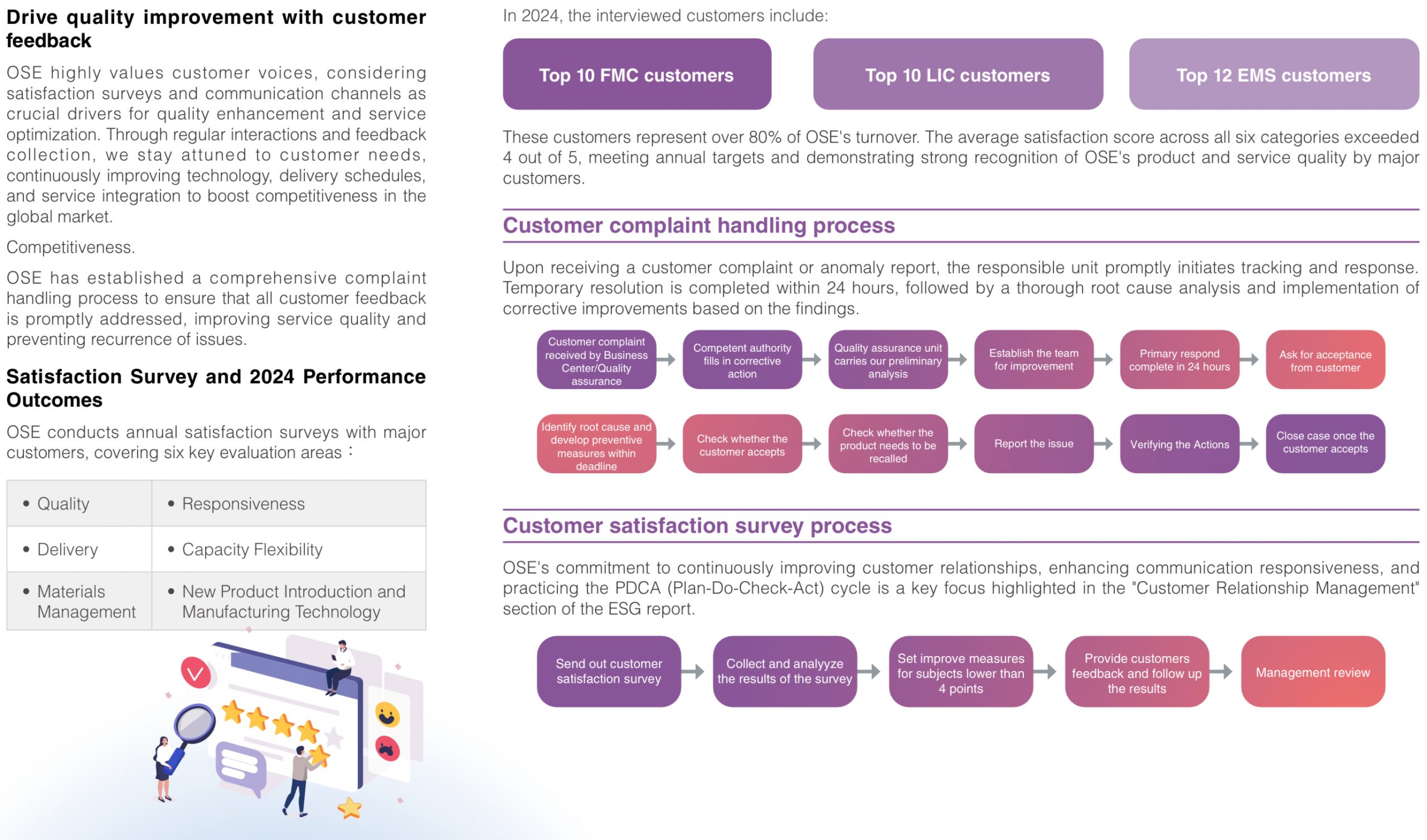

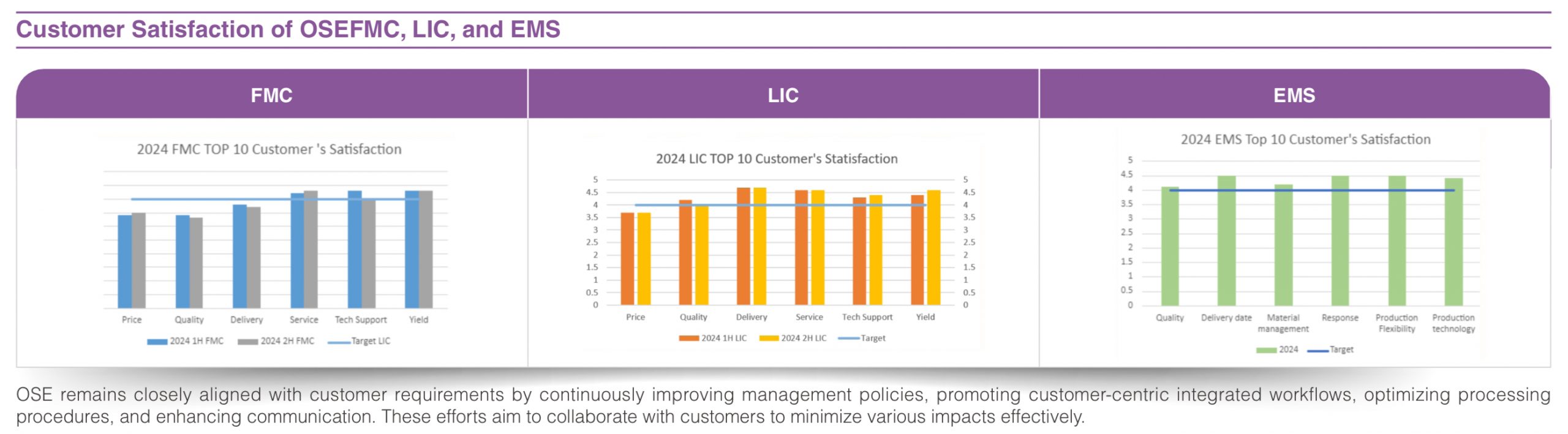

Product quality management

Quality management system establishment

Stable product quality is fundamental to the company’s long-term operation and customer trust. OSE fully implements internationally recognized quality management standards to build a robust quality system foundation, including:

• ISO 9001 (Quality Management)

• ISO 13485 (Medical Devices Quality)

• IATF 16949 (Automotive Industry Quality)

• AS 9100 (Aerospace Quality)

Based on these standards, a comprehensive quality manual is maintained, with regular internal and external audits and management reviews conducted to continually enhance quality policies and performance outcomes.

Process control and continuous improvement

Focusing on timely delivery and product quality, OSE employs multiple quality control tests and automated equipment across the production process to ensure:

- Multi-stage quality assurance testing and process audits to prevent defects from progressing to subsequent stages.

- Use of automation to reduce manual dependency, enhancing consistency and efficiency.

- Encouragement of R&D and manufacturing innovation to improve yield and increase customer satisfaction.

Additionally, collaboration with Total Quality Management (TQM) initiatives and ongoing employee training fosters a strong quality culture and solidifies the quality management foundation.

Quality purpose and performance

OSE is customer-centric, delivering competitive packaging, testing, and electronic manufacturing services through rocess innovation, information technology applications, and flexible production capabilities. We strengthen communication and trust with key domestic and international customers via ultiple platforms.

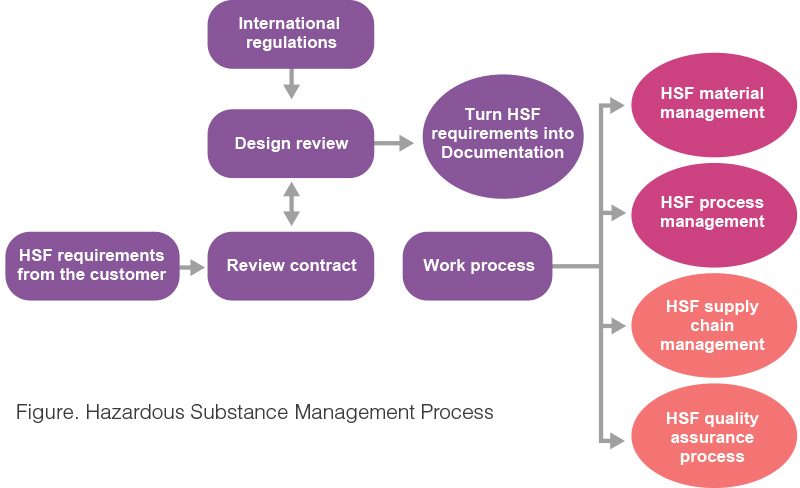

Hazardous substances free (HSF) management

To comply with international environmental regulations and meet customer safety

requirements, OSE has initiated the following in 2024:

• Adoption of IECQ QC 080000:2017 Hazardous Substance Process Management System, with third-party verification expected within the year.

• Completion of 82 hours of related education and training.

• Establishment of management procedures for hazardous and environmentally relevantsubstances.

• Implementation of material control based on the IEC 62474 controlled substances list,adhering to RoHS, REACH, and other directives.

• Close collaboration with suppliers for source management throughout procurement, production, and inspection stages.

✓ 2024 Results

• No violations of product health and safety regulations.

• No sales of products containing substances restricted by international hazardous substance regulations.